San Marco Ltd mechanical construction industries was created in 1962. Initially our market was addressed on construction and outfitting of tipper bodies for trucks, we then widen our manufacture to road safety and railroad products. By the end of the 70’s the company become leader of buffer for rail wagon.

In the 80’s a sensitive investment policy on research and technology enabled the export of our products in Europe and North-Africa as well as Near East. In the 90’s as we expanded our warehouse and we got equipped to start producing caissons for FIAT DUCATO and IVECO DAILY and for military vehicles.

The 1st of April 2017 Scattolini s.p.a from Valeggio sul Mincio bought the company and since then we are Sanmarco Industrial Ltd. and it is proceeding with cataphoresis and caissons outfitting for the main vehicle producers. Most of the component we use to produce our outfitting have been planned, patented e produced by factories of Faist Group led by Scattolini Ltd.

The company has a factory in Atessa for superficial treatment of the steel with powder and liquid cataphoresis painting system. The factory covers 40.00 square meters, 12.500 of which are roofed and used for the final mounting of the caissons and the harness of special vehicles.

Sanmarco Industrial is the leader in Italy for production of outfitting for commercial vehicles.

Using innovative material together with experience, advanced technology and advanced research allowed us to gain high quality and gave us the opportunity to become partner with the major vehicle producers.

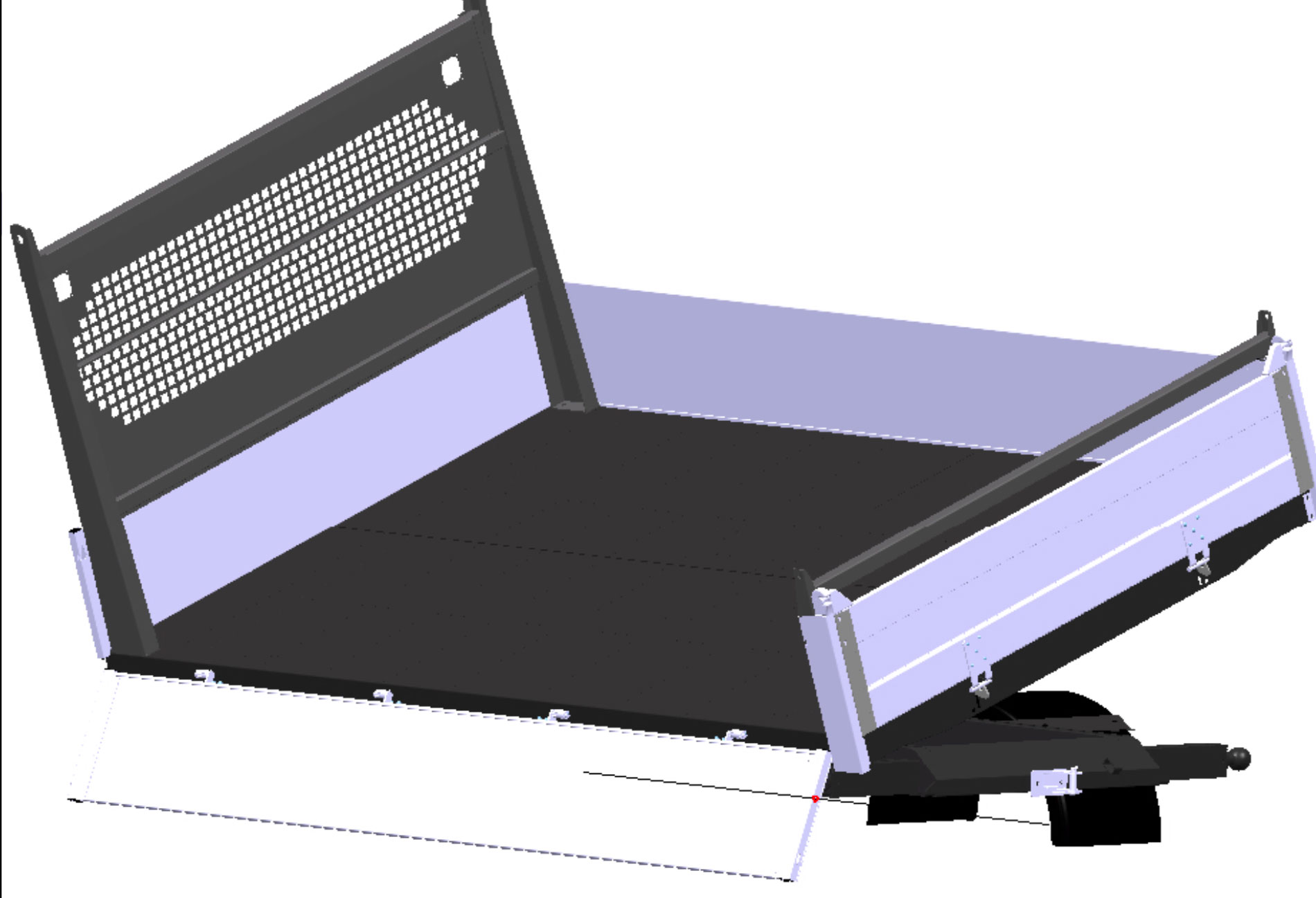

Part of the components are designed and patented by Faist group and Scattolini s.p.a. is part of this group too. ![]()

![]()

Thanks to modern software that the company uses we can realise solid modelling of details during the designing phase and subsequently assembly of all the parts to get the final result.

The study the mechanical behaviour of the structures functionally with the materials used and with the system of force and acceleration allow us to have a preliminary execution of a mesh on a 3D model and later the use of the FEM form.

ENVIRONMENTAL POLICY

The company Sanmarco Industrial S.p.A. evaluates as priority the need of constant improvement of the environmental compatibility during all its production processes, complying with the environmental legislations going forward a sustainable development.

This policy is disclosed to everyone who works with and for Sanmarco Industrial S.p.A., it is shared with the public and within all level of the organization, enforced and reconsidered at least once a year on the occasion of the management review process in order to guarantee the effectiveness and eligibility.

With the policy hereby Sanmarco Industrial S.p.A. agrees to:

- Deal with all the steps of the production processes in accordance with environmental regulations applicable to its business and other requirements to which the company subscribes related to its environmental aspects and sector specific rules, encouraging an effective policy of prevention and environmental protection;

- Fulfil the environmental management system standard requirement;

- Regular evaluation of the system performance and compliance with the applicable environmental legislation;

- Setting and reviewing at least once a year the environmental objectives and targets;

- Remove all the nonconformities with the environmental requirement;

- Implement correctives and preventives actions to prevent the recurrence of nonconformities;

- Monitor the environmental aspects of its activities in order to carry out actions to minimize the environmental impact;

- Provide human, financial, operational, commercial resources and the appropriate technology to ensure compliance with the targets.

WATER PURIFIER

Our water purifier is a physic-chemical plant and can purify wastewater of the different production processes above mentioned.

The system is handled by our laboratory which is provided with specific equipment like JAR test, spectrophotometer and micro-digester) in order to guarantee the control on the wastewater treated and so to maximise the synergies among them.

The system can purify circa 150m3 per week, the system is equipped with digital instrumentation to better control the quality of the purified solution put into the grid.

CERTIFICATE

Our offices